- Home

- Products

- Gravure Coating machines, Squeeze Roll Coater

- Gravure Coater Type SC-RO20, Reverse Osmosis Membrane Coating Line

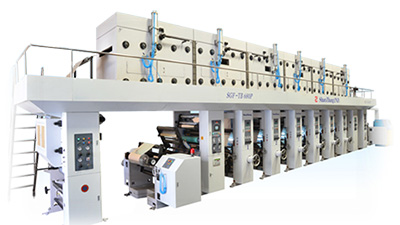

Gravure Coater Type SC-RO20, Reverse Osmosis Membrane Coating Line

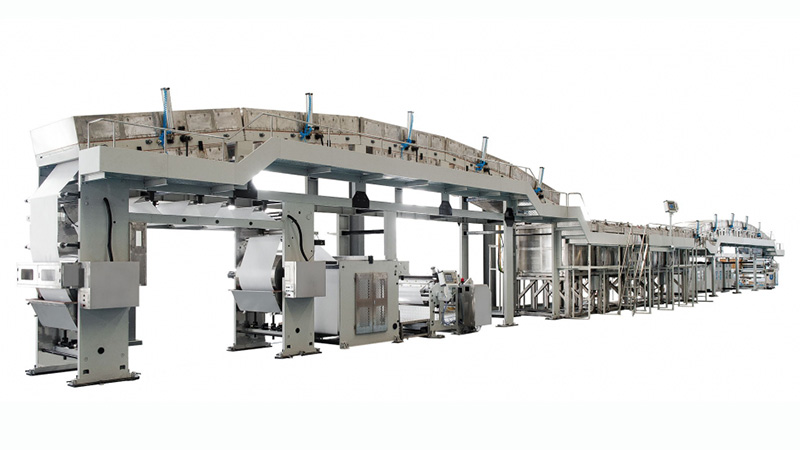

SC-RO20 reverse osmosis membrane coater is a gravure coating unit used in RO membrane processing. This gravure coater integrates dip coating (immersion coating) with slot die coating techniques. The slot die coating is a high accuracy coating method for deposition of a liquid film to the surface of a substrate. The liquid is pumped to the slot die coating head where can transform the liquid into ultra-thin coatings and transparent optical coatings, while the amount of coating is precisely controlled within a defined tolerance.

The reverse osmosis membrane coater has a double walled coating fluid tank, which is made of corrosion resistant stainless steel to adapt a variety of chemical liquids in dip coating process. Furthermore, guide rolls and other accessories contacted with chemical liquids are all corrosion resistant.

Specifications

Machine speed: 20m/min

Coating method: dip coating

Coating substrate: nonwoven fabrics, weight 100g/m³

Coating thickness: 0.12-0.16mm

Tension range: 40-200N/full width

1. Independent unwinder is equipped with web guiding function.

2. The unwind unit is independently driven by servo motor, with closed-loop tension control for active unwinding. And alarm warns when roll diameter is less than specified value.

1. Receiving method: receiving rolls in smooth motion, remaining the tension.

2. Receiving operation time: 2 mins; Web length: ≥30 meters;

3. Equipped with sensor for controlling of web stroke, electrical and mechanical limit switches are available.

4. Webs in-feeding is positioned above the operation section.

5. Webs are in-fed by pull rolls.

1. The coating fluid tank is designed with insulating layer, inner tank is made of S316L stainless steel, while the outer tank material is S304 stainless steel, and filled with insulating material in between.

2. Insulating layer is supported with stainless steel profiles.

3. Stainless steel structure supports tank body.

4. Drive roll tension is controlled in real-time state and displayed on operator interface.

1. Independent rewinding unit is equipped with web guiding function.

2. Driven by servo motor independently, accomplishing automatic feeding. PLC system is used for automatic taper tension control.

1. Drying length of 16 meters in first drying stage, and drying length of 20 meters in second drying stage.

2. Guide rolls in drying channel are driven by independent motor.

3. Drying chamber has double-layer insulation structure, inner layer material is S304 stainless steel while the outer layer material is carbon steel. Air pipe is made of stainless steel.

4. Double-side hot-air drying, temperature and air volume both are adjustable, with real-time temperature display.

5. Max. temperature reaches 100℃, with accuracy ±2℃.

-

- Guangdong Shanzhang Industry Co., Ltd.

+86-754-88226188

+86-754-88226188

Manufacturing capability  Plant exterior view

Plant exterior view

Company entrance

Company entrance Assembling workshop

Assembling workshop

- Service

Pre-sales consulting

Pre-sales consulting

After-sales service

After-sales service Other services

Other services

End-use sectors