- Home

- Products

- Gravure Coating machines, Squeeze Roll Coater

- Squeeze Roll Coater Type SC-MP150, Mineral Paper Coating Machine

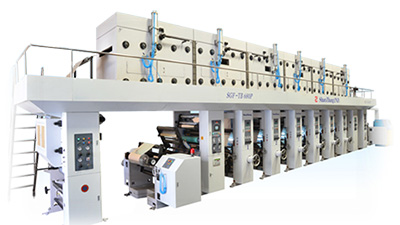

Squeeze Roll Coater Type SC-MP150, Mineral Paper Coating Machine

SC-MP150 mineral paper coating machine applies water-based coatings on the surface of mineral paper, it is widely used in production of printings and paper products, such as decorative wallpaper, packaging carton, cards, labels and tags, etc.

The coating process can enhance the surface smoothness of mineral paper. Considering that the mineral paper is weak in tension and easy to be torn, so this mineral paper coating machine is designed with low operation speed.

Specifications

Machine speed: 150m/min

Coating method: anilox roll, coating on both front and back sides of web, once on each side.

Coating substrate: LLDPE film, thickness: 100-250μm

Coating thickness: dry adhesive about 10-50μm

Tension range: 40-400N/full width

1. Reversible independent turret unwinding with dual-shaft double working positions.

2. Edge position control (EPC) for automatic web guiding.

1. Gravure coating and cylinder coating methods can be used in combination according to the actual needs of the process.

2. Applicator roll is driven independently by servo motor, and is running synchronously with the motor for laminating by means of PLC control.

3. Glue spreading is cycled automatically.

1. Calender roll has a hard chrome plated surface, and equipped with steel back-up roll.

2. Cooling roll is made of hard chrome plated steel, the cooling method of which is circulating water cooling.

1. Reversible independent turret rewinding with dual-shaft double working positions.

2. AC variable frequency drive with closed loop vector control, and PLC system for automatic taper tension control.

1. Hot air nozzle has maximum flow speed of 20m/sec.

2. Drying chamber is opened and closed pneumatically.

-

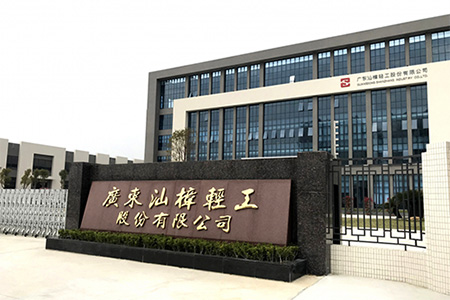

- Guangdong Shanzhang Industry Co., Ltd.

+86-754-88226188

+86-754-88226188

Manufacturing capability  Plant exterior view

Plant exterior view

Company entrance

Company entrance Assembling workshop

Assembling workshop

- Service

Pre-sales consulting

Pre-sales consulting

After-sales service

After-sales service Other services

Other services

End-use sectors